Commercial Self-Leveling Compound 830

$41.45

To purchase a larger quantity of this product, please contact us.

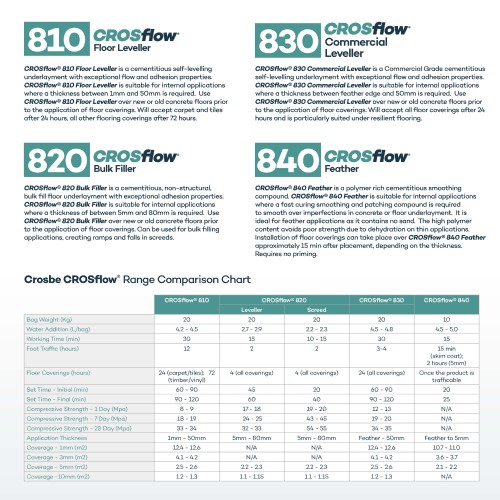

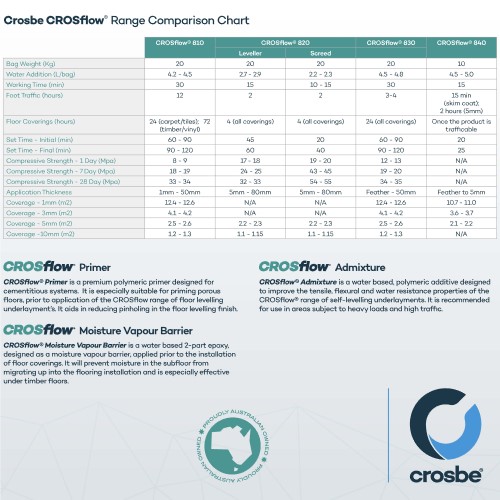

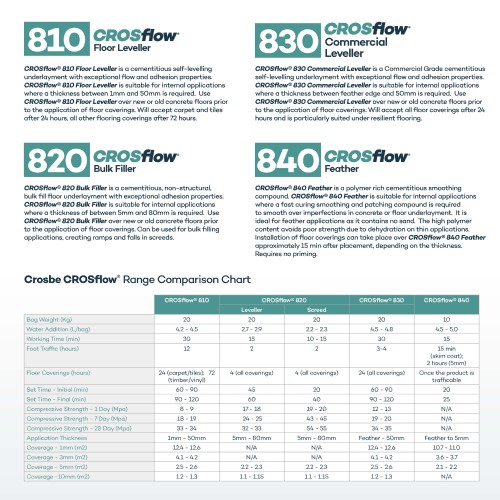

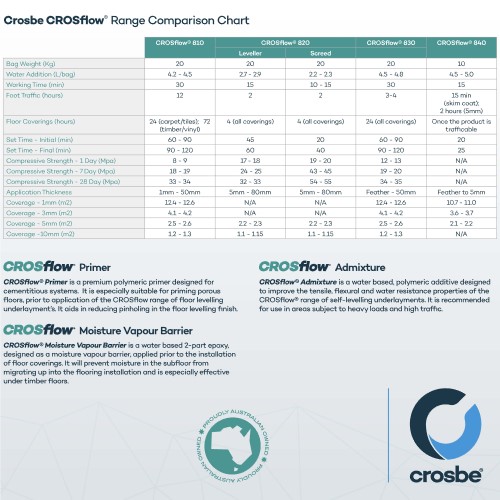

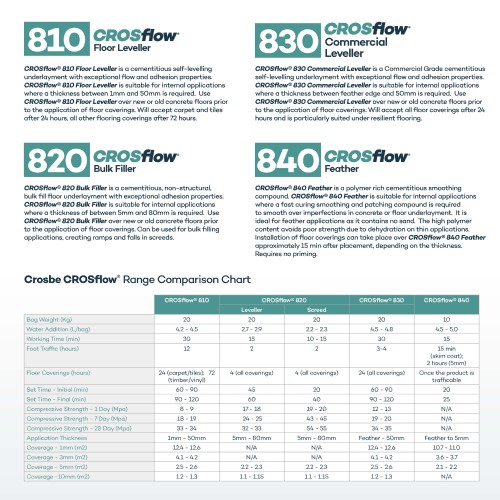

Contact usCommercial Self-Leveling Compound 830 is a commercial-grade self-leveling underlayment with exceptional flowability and adhesion. CROSflow® 830 Commercial Leveler is designed for interior and exterior work where a thickness of up to 50 mm from the edge of the feather is required. The purpose to use commercial self-leveling compound 830 is to fix uneven existing new or old concrete floors before applying floor coverings. This leveling mixture is suitable for all floor coverings after 24 hours and is especially suitable for resilient floors.

Concrete floors must be durable, clean, and dry. The surface must be free of dust, dirt, wax, grease, asphalt, latex and gypsum compounds, adhesives, paints, hardeners and sealants, and other contaminants that may destroy adhesion. Concrete should be free of grout and efflorescence and should not be subjected to hydrostatic pressure. Mechanically prepare the floor using recommended preparation methods such as shot blasting, diamond grinding, or other suitable methods to produce a rough, clean, firm, hard, and open porous surface. Acid etching is not an appropriate base preparation method. Remove all dust and debris from the floor by vacuuming the surface with a suitable Class H industrial cleaner, which must be equipped with a Hepa filter.

All concrete bases must be completely cured and dry in accordance with AS 1884 (relative humidity less than 75% when measured in accordance with ASTM F2170). Ambient, surface and material temperatures should be maintained above 10°C and below 35°C. For floors with high moisture content or those prone to rising humidity, use a moisture barrier.

Using a soft brush or broom, prime the prepared concrete area with CROSflow® Primer and allow the primer to dry. A second coat of primer may be necessary for areas with very porous surfaces where the first coat has fully absorbed. Allow the primer to dry completely before applying CROSflow® 830 until a clean, thin film is formed (approx. 1-2 hours depending on ambient conditions). Low temperatures may extend the drying time of the primer. Do not apply the leveler until the primer is completely dry.

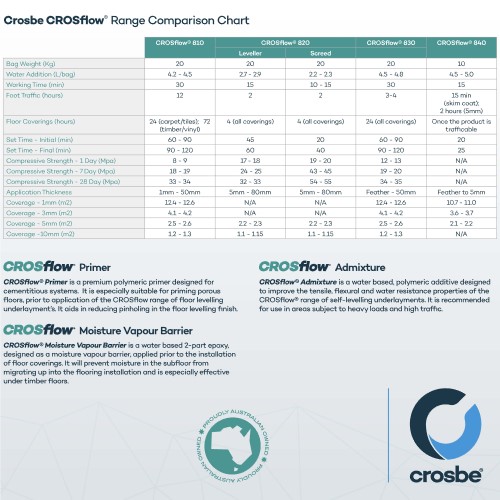

Place the recommended 4.4-4.8 liters of potable water into a clean mixing container and, while stirring, slowly add all 20 kg of CROSflow® 830 contents. 600 rpm. Stir for approximately 2-3 minutes until homogeneous without lumps. Be aware of the temperature when using it externally.

Use the mixture within 15 minutes of mixing, making sure to mix only the amount that can be used within this time. This is especially important when used in an outdoor environment.

Pour the mixed CROSflow® 830 onto the prepared substrate and spread it in place using a calibrated long-handled trowel. CROSflow® 830 will reach its level within the first 10-15 minutes after pouring. Subsequent application of the leveler should be made while the material on the floor is still liquid and has a damp edge to ensure easy mixing. CROSflow® 830 can be applied up to a thickness of 50 mm at a time. Thicker applications may require a longer cure. When applying externally, be aware of the substrate temperature when applying.

Spiked boots are recommended to minimize any dents in the level gauge while it is still liquid.

CROSflow® 830 can be pumped using an efficient piston pump. It is recommended that the pump manufacturer’s instructions be followed carefully.

Allow 3-4 hours of curing time at 23°C for pedestrian traffic. Allow CROSflow® 830 to dry for 24 hours at 23°C before applying a suitable floor coating. This time frame may be affected by air temperature, substrate temperature, and relative humidity. Thicker coats increase the drying time.

A 20-kilogram bag of CROSflow® 830 will cover approximately 4.1 m2 with a thickness of 3 mm and 2.5 m2 with a thickness of 5 mm.

Wash all tools in water immediately after use.

The mechanism of interaction between cement and water depends on the temperature. The setting time slows down at low temperatures and accelerates at high temperatures. Water and ambient temperature ranges are recommended to avoid significant changes in setting time:

The shelf life of the product is 18 months from the date of manufacture, subject to storage in closed rooms in accordance with the recommended storage conditions.

Store in a dry place, in unopened and undamaged plastic bags, at temperatures below 30°C. Shelf life may be shortened if stored at excessive temperatures, outdoors, or in high humidity conditions.